How The Custom Design Process Works

Truly original jewelry designed from scratch.

Step 1 – Designing & Modeling

Initial Design

We take a look at your ideas, examples of other pieces, and any reference material that can be used for inspiration in order to find the perfect design. After acquiring the main elements for the design, our jewelry designer will begin creating a unique design, typically with a few variations. This can take several days depending on the complexity of the piece. The design is created using our advanced CAD (Computer Aided Design) software.

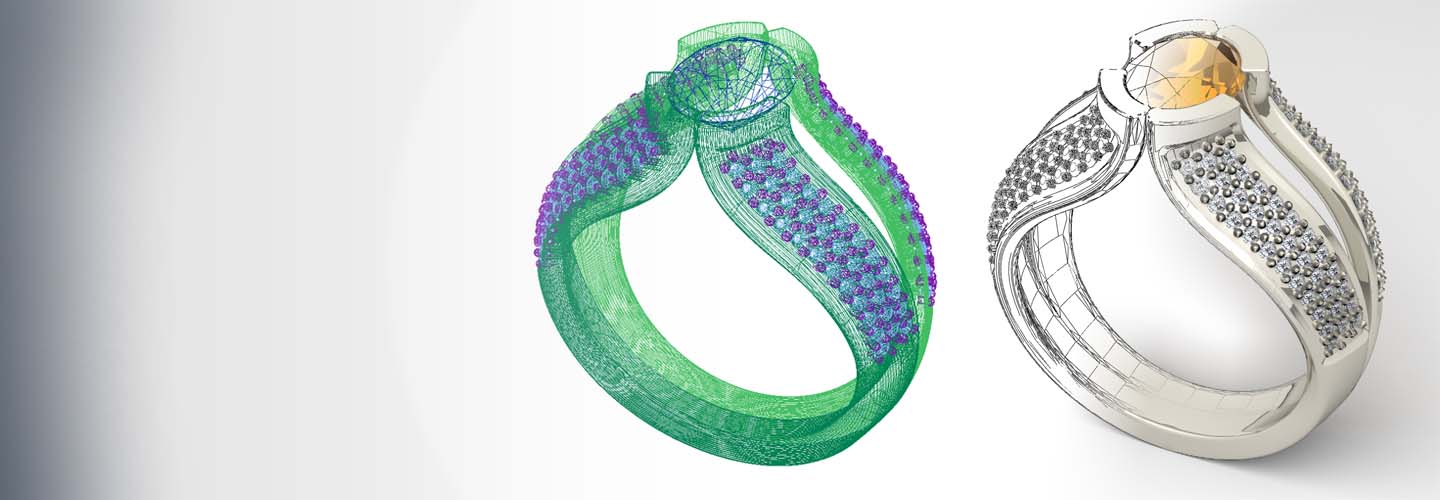

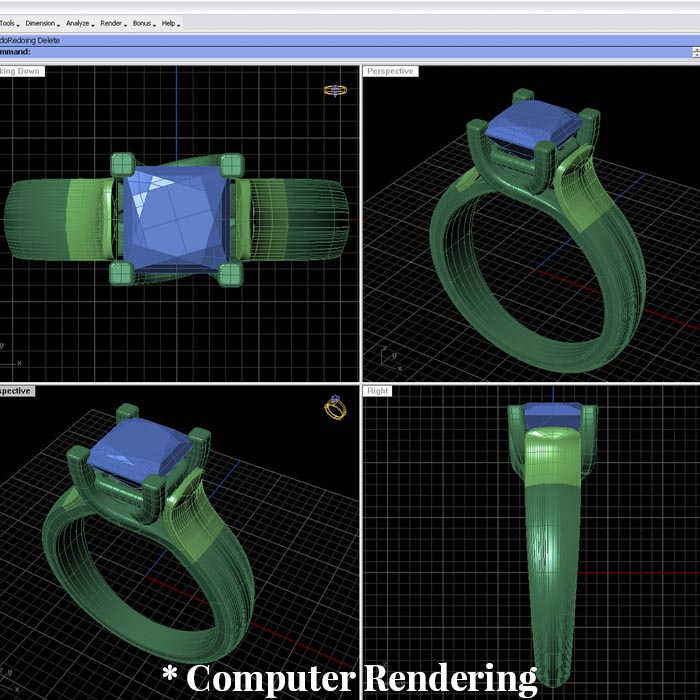

3D Modeling & Rendering

Our designer starts by making a rough model of the jewelry piece using our state of the art 3D computer modeling software. From there, the design is fine-tuned by adding more detail until it looks more like the piece you are after. Our custom jewelry designer will actually work with you to perfect the design. And with over 30 years of jewelry design experience, our CAD modeler knows how to get the design looking just right. After the design is complete, we will show you the realistic renderings of your custom jewelry piece, giving you the opportunity to approve the final design.

Step 2 – Wax Milling & Carving

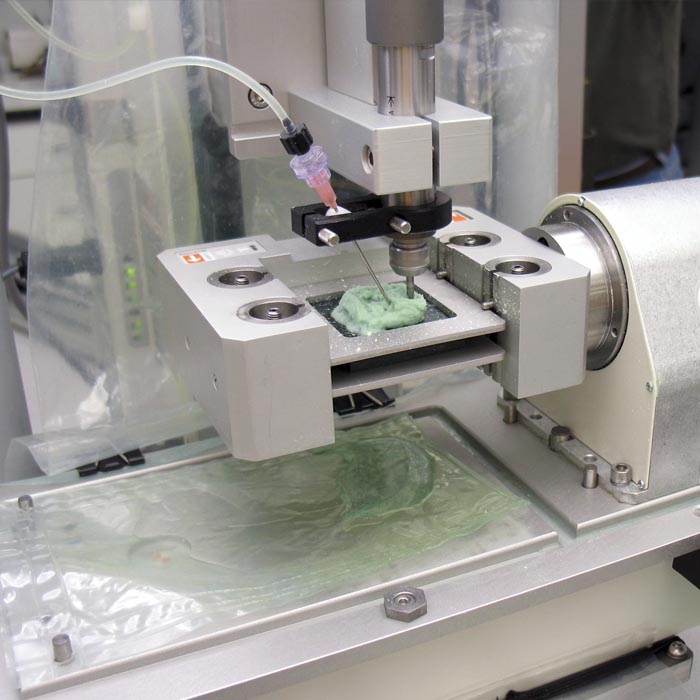

Wax Milling

After the final CAD design is approved by you, we can begin the actual creation of your custom jewelry piece. Using the finished CAD design, our specialized milling machine makes an exact wax replica. It uses high pressure water to cut the hard wax to specification. This wax master model can even be viewed by you to give you a more realistic idea of the shape and size of the finished piece of jewelry.

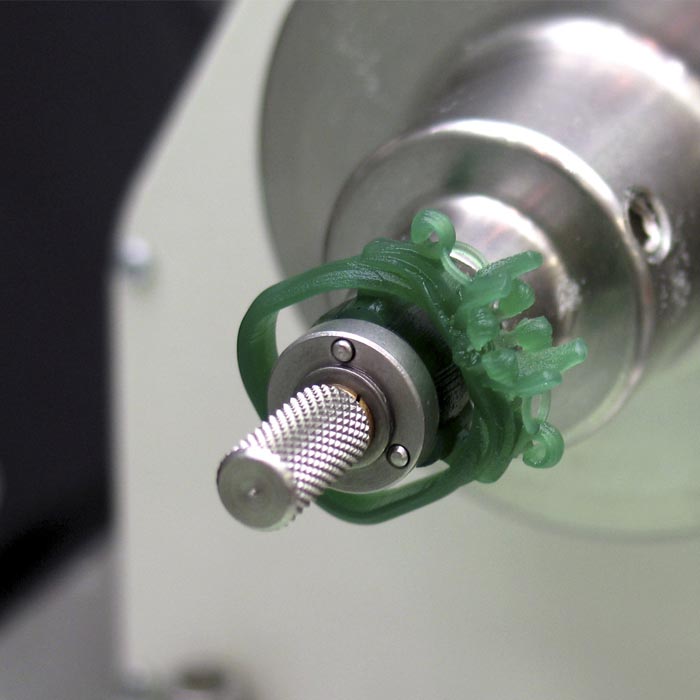

Wax Carving

To add an extra touch of artistry, we sometimes need to hand carve parts of the wax models. This gives the piece a unique blend of detailed design and artistic touch. The finished hand carving can be shown to you before we move on to the next step of the custom jewelry design process.

Step 3 – Casting, Detailing & Polishing

Casting

After the final wax model has been approved by you, the jewelry is ready for casting. We cast our jewelry in-house using world class platinum and gold casting equipment. The cast is made with detailed precision, allowing us to produce accurate and beautiful one of a kind pieces of jewelry.

Detailing & Polishing

When castings are complete, they come out with a smooth but matte finish. As a result, it’s necessary that we hand work the castings in order to bring out the perfect gold, platinum, or palladium finish. This is truly specialized work that takes skill and extreme attention to detail. After the final polishing work is done, your jewelry will come out with a magnificent shine.

Step 4 – Stone Setting

Stone Setting

Now that we have a nearly finished piece of jewelry, it’s time to add the stones. Setting stones is a skill that takes many years to master. Each stone is laid out and meticulously fitted into the metal with accuracy and precision. The metal is carefully moved by hand in order to securely fasten the stones in place. This hand setting process ensures that the stones are fit perfectly in place in order to prevent them from ever falling out.

Timeline & Pricing

Custom Jewelry Design Timeline

The entire process from start to finish will vary depending on the complexity and detail of the desired jewelry design. But on average, the process is completed within 3 to 6 weeks.

Custom Jewelry Pricing, Estimates & Payments

Estimates do not necessarily reflect the final price of a given piece of custom jewelry.